Simply speaking, it is the fiber coupler that melts and pulls on the taper machine using the fusion taper technology. The so-called fused taper technique is to bind two or more optical fibers together, and then melt and stretch it on a taper. During the stretching process, the optical fiber coupling and splitting ratio of each optical fiber is monitored, and the melting ratio is reached after the ratio of optical fibers reaches the requirements. One end retains one fiber (the rest is cut off) as an input and the other as a multiplexed output.

Optical fiber fusion taper simple principle: the basic method of melting taper is to pull the two fibers or more) to remove the coated fiber in a certain way, melt under high temperature heating, while stretching to both sides, and finally heating The zone forms a special waveguide device with a double-cone structure. When two fibers are fused, the input optical signal enters two fibers from one fiber. Assuming that the two fibers have the same specification and the input optical power is P0, the optical power distributions of the two fibers in the pull coning process are Pocosz and inz, respectively, where input is the coupling constant determined by the parameters such as fiber core diameter, input light wavelength, and the like. Pull cone length. In the case of the determination of the type and wavelength of the optical fiber, precise control of the length of the taper, the size of the melting zone, and the melting temperature can be made according to the distribution change of the optical power, and various optical coupling devices can be made.

Optical fiber fusion taper is a high-precision, high-efficiency, high-reliability, compact, and easy-to-use manufacturing system for mass-producing fusion fiber couplers, especially ultra-low extra loss (typically 0.05dB) standard fiber Couplers, broadband fiber couplers, wavelength division multiplexers, and other fusion fiber couplers are highly repeatable.

The taper machine is a high-precision, high-efficiency, high-reliability, compact-structured manufacturing system for the mass production of fiber couplers.

The taper machine is a complex system that mainly involves: mechanical devices, electronic control systems, combustible gas systems, and vacuum pump systems.

â—† Among which mechanical devices mainly include

Fiber Clamp: Used to fix the fiber position on the taper

Stretching platform: the carrier responsible for drawing the fiber during the melting process

Torch moving platform: moving the torch heating fiber in the left and right of the optical fiber

Package Gripper Mobile Platform: Used to encapsulate fiber after melting is complete

â—† Electronic control system includes

Computer: There is a complete software in the PC to control the entire process of monitoring the taper

I/O interface: for digital analog processing, output control, control of flame, gas switch

Stepper Motor Control: Six stepper motors are used in the torch heating, stretching, and package motion control of the fiber.

Optical signal detectors, optical switches, and package heaters

â—† Combustible gas system: including pressure regulating valve, proton flowmeter and hydrogen leak alarm

â—† Vacuum pump system: used to hold fiber in vacuum

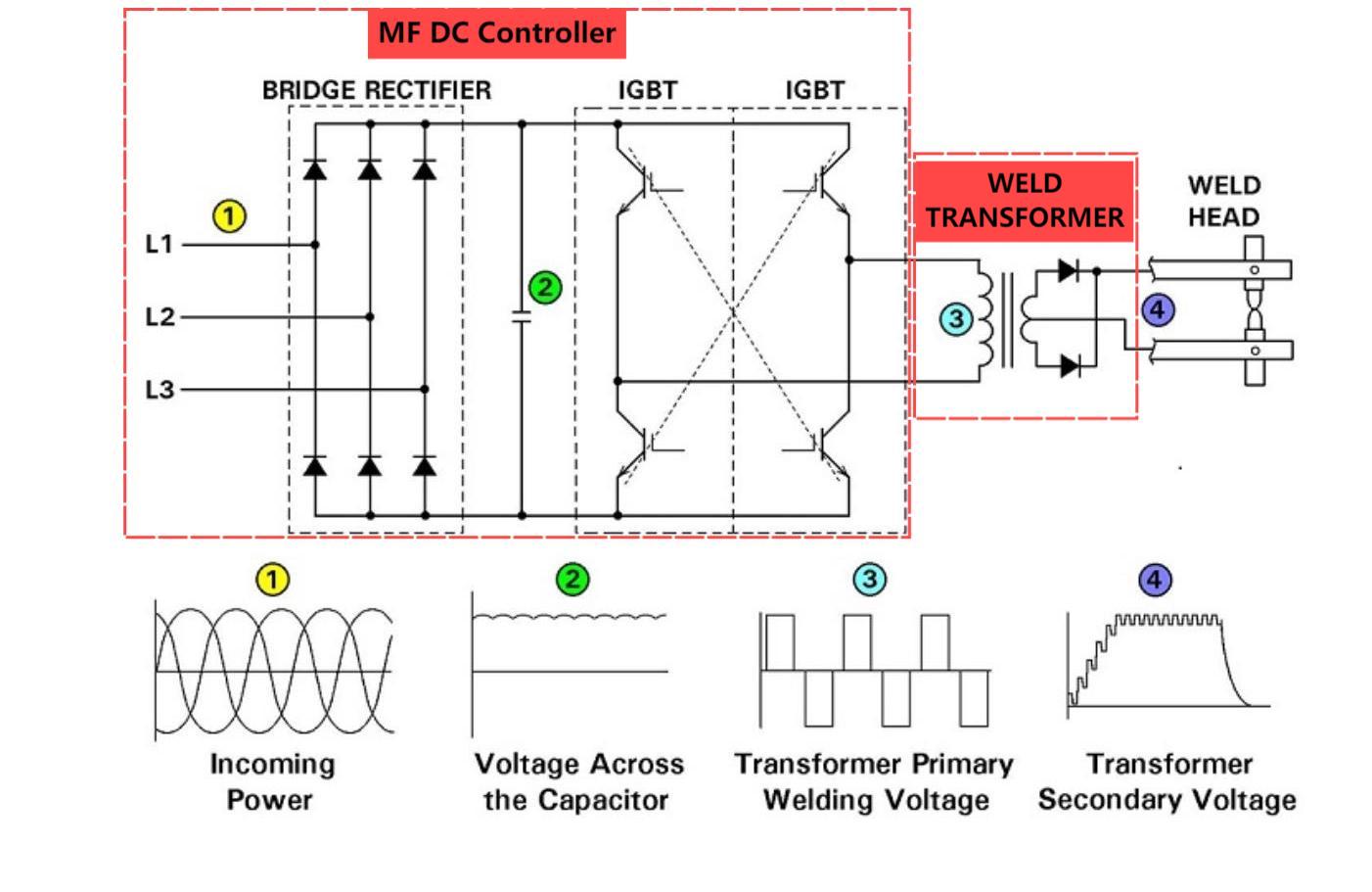

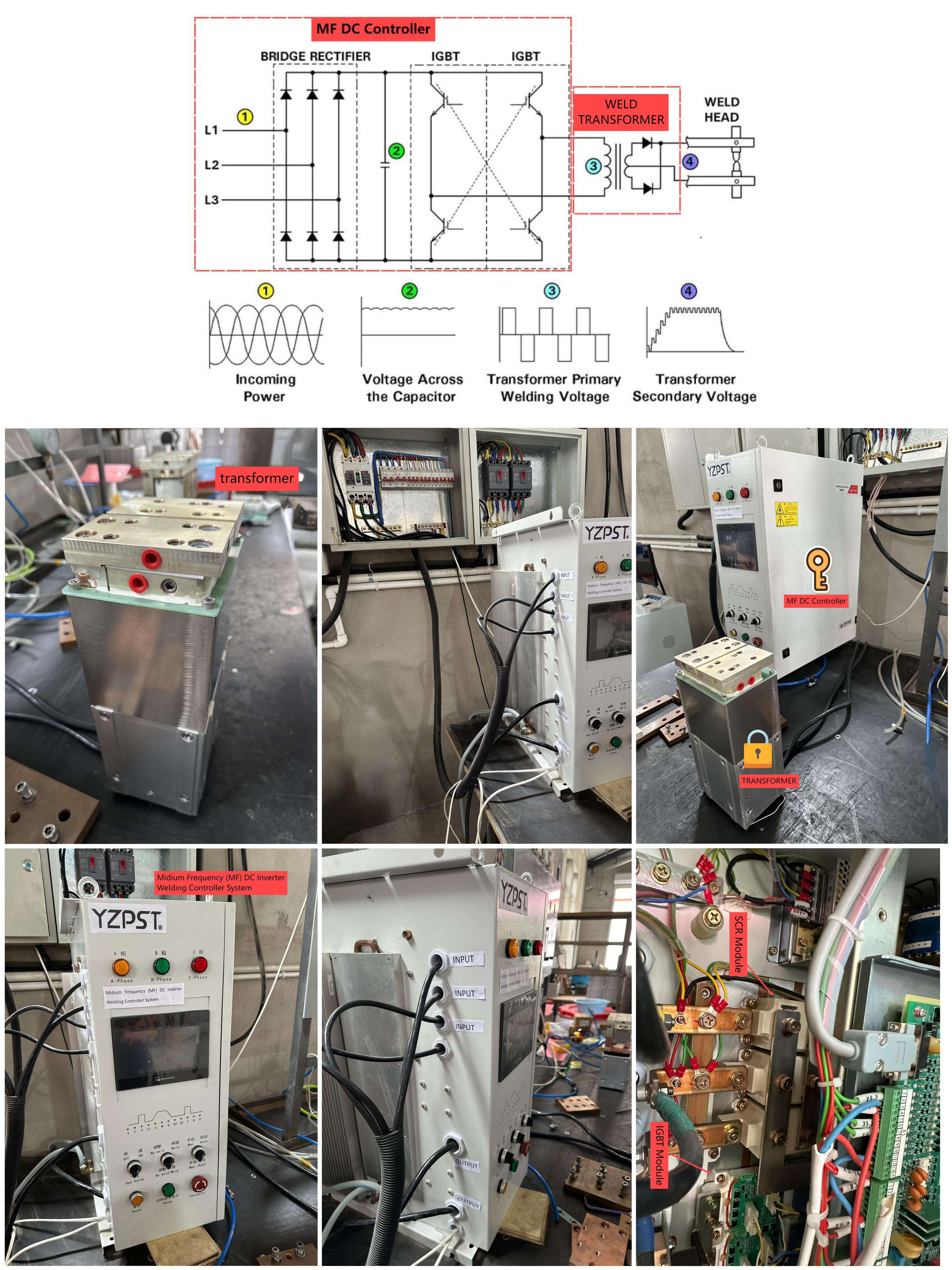

The entire system configuration is shown in the figure below:

![]()

![]()

Different manufacturers use different methods to control the stepping motors. However, there are some problems such as large amount of heat, unreliability, and instability. Some manufacturers are seeking to develop their own control products to solve this problem. The action of the six stepper motors used in the taper machine is explained. Summarized as long as used to control the movement of the torch, fiber stretching and fiber optic packaging. In the torch control stepping motor to achieve 3-dimensional heating, front and rear, up and down, left and right different angle heating fiber. The stretching platform drives a bidirectional rib screw by a stepping motor to stretch the optical fiber in two different directions when the motor rotates. Both sides of the optical fiber are equipped with a packaged device that is controlled by two stepper motors for back and forth motion. The specific control is that when the torch three-dimensionally heats the optical fiber, the stretching platform stretches the optical fiber, and the optical fiber is packaged by the package portion after the optical fiber has a split ratio. It is a heating and stretching that are performed simultaneously, and the sealing process is performed in sequence.

At present, most manufacturers have separate control and data acquisition for the stepper motor, so as to increase the volume. For example, some manufacturers use two 3-axis control cards + data acquisition cards + six step drivers + IPCs. The problem with this is that there are at least 36 lines between the two control cards and six drivers plus the power line. In addition, the heat and electromagnetic interference generated after starting the machine in a control box with more than 60 lines of 24 lines from the motor to the driver seriously affect the performance. Some control cards are inserted into the PCI slot of the computer and sometimes the contacts are poorly connected. , Separation of motion control and data acquisition increases the difficulty of controlling software. Many manufacturers are looking for a better solution: If all the control, drive, and data acquisition of the six stepper motors can be completely concentrated on one PCB, then the above problems can be solved, but it has been stepping due to technical limitations. The volume of the driver is very difficult to do very small. Nowadays, the low-power design of the step-driver chip in foreign countries has come out with a lot of heat dissipation, and the volume problem can be solved.

![]()

![]()

TRINAMIC, a German semiconductor company, has been working on the control of stepper and DC brushless motors. It has successfully developed a number of patented technologies to reduce costs for customers. The TMCM-612 module developed by the company integrates the control drive and data acquisition functions of the 6-axis stepping motor. The specific performance is as follows:

â— The 6-axis stepping control and drive are integrated on the board, and the data communication between the control chip and the driver chip can be realized through the bus communication. The virtual closed-loop control is realized and the controller can read the position of the motor at any time. The patented stallGuard function of the patented technology can effectively avoid overload and lost motion. Only need to connect 6 steps directly to the corresponding terminal, and each motor is equipped with plus and minus two limit inputs.

â— The I/O port provides 8 I/Os that can be programmed for digital output or digital input or 10bit analog input; 8 16bit ADC analog-to-digital conversion inputs; 8 10-bit DAC digital-to-analog outputs. The card provides a total of 24 I/Os to meet the flame, gas, and detection data collection

â— The data transmission speed can be increased by using USB or RS232 and PC communication, especially USB.

â— Because the card is not used in the "control-drive-motor" design, it is not an ordinary one-way control. Instead, it uses an internal closed-loop control, ie, control-drive-motor, to exchange data at all times. The central controller can change the target position at any time. This change is timely, and unlike other controllers, it must wait until the previous position is reached before the next target position can be executed. This has the advantage of being able to control the length of the stretch in the shortest possible time.

The real-time position change function is critical to the taper. When the conventional controller is in position control, the next position control can only be executed after the current position command is completed. If a problem occurs after stretching, it cannot be remedied in time. The TMCM-612 can change the target position in different states of the motor as shown in the figure below

The application of the TMCM612 on a taper has the following advantages:

â— Reduce system wiring and improve the system's anti-jamming capability

â— Concentrate all motor control, drive and data acquisition functions on a single board to save equipment volume and reduce the probability of failure

â— Immediate change of target location will improve product quality

â— Highly integrated design reduces hardware and software design workload

â— Compared with separate control cards, drivers, and data acquisition cards, the TMCM612 will significantly reduce the cost of the equipment.